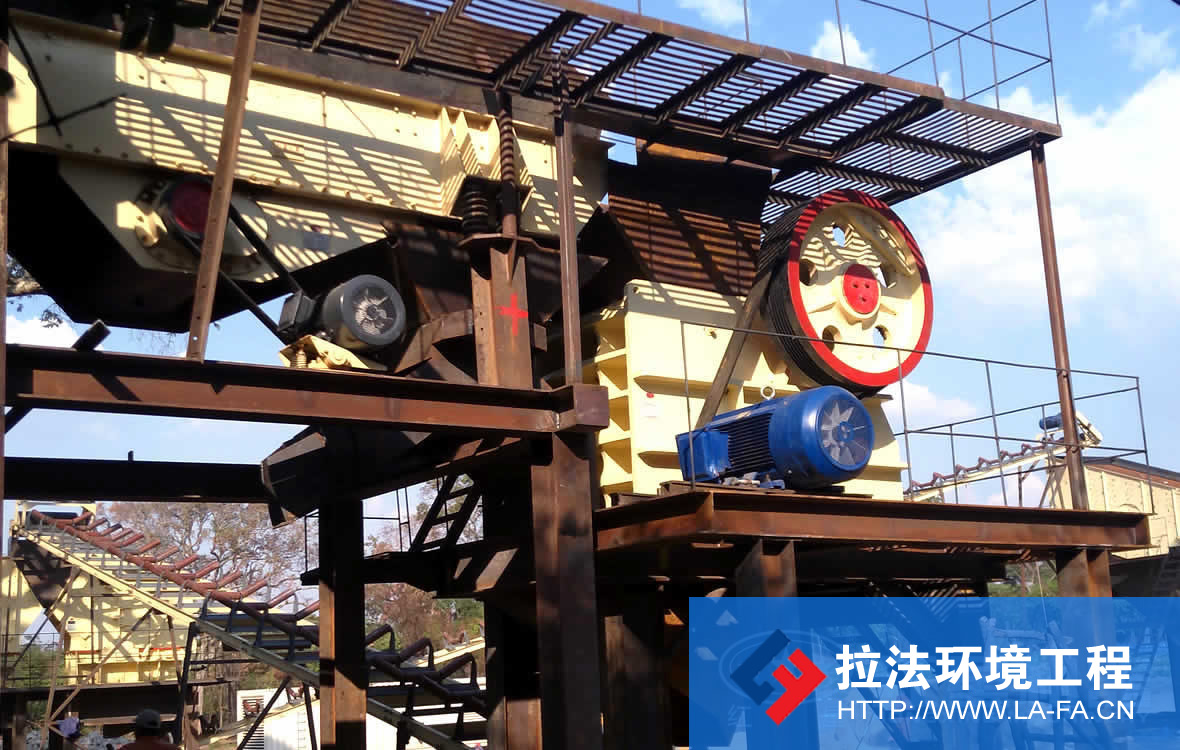

Shandong Rizhao 300t/h building special stone production line

Processing capacity: 300t/hProcessing capacity: Granite, limestoneDevice Configuration: Jaw crusher, impact crusher, sand making machine, sand washing machine, vibrating feeder, belt conveyor, etc.Shandong Rizhao A Processing Factory is a stone factory specializing in the processing, production and sales of special stone materials for construction. Its main products are granite, basalt, river pebbles, etc. It has a scientific and reasonable quality management system and has very high quality requirements for stone production lines.

The customer's appraisal is a good explanation, the gold cup silver cup is inferior to the customer's reputation, we use very diligently, trades your approval.

This production line produces fluorite powder with high precision and low impurity content, which satisfies the high quality requirements of our company and greatly improves the recovery rate. After putting into production, the process flow is very smooth, the failure rate is very low, the wear resistance of each component is good, the operation efficiency is high, our company is very satisfied.

They are the mining industry leaders who have served in Lafa, and they are more powerful proof of the product quality of the Lafa program; their needs may be similar to yours, and they will be a valuable reference for you to enter the industry.

Copyright @ Nanjing Lafa Environmental Engineering Co., Ltd Hotline:025-86118737